Design Ethos - Stair Casing The Solar System

In order to get to Mars and effect an entrance with a safe sustainable concept, a sound Human plan should include flexibility and safe redundencies in design. Mars will need to be terraformed prior to a large sustainable community set-up. [See Mars Terra Augmentation]

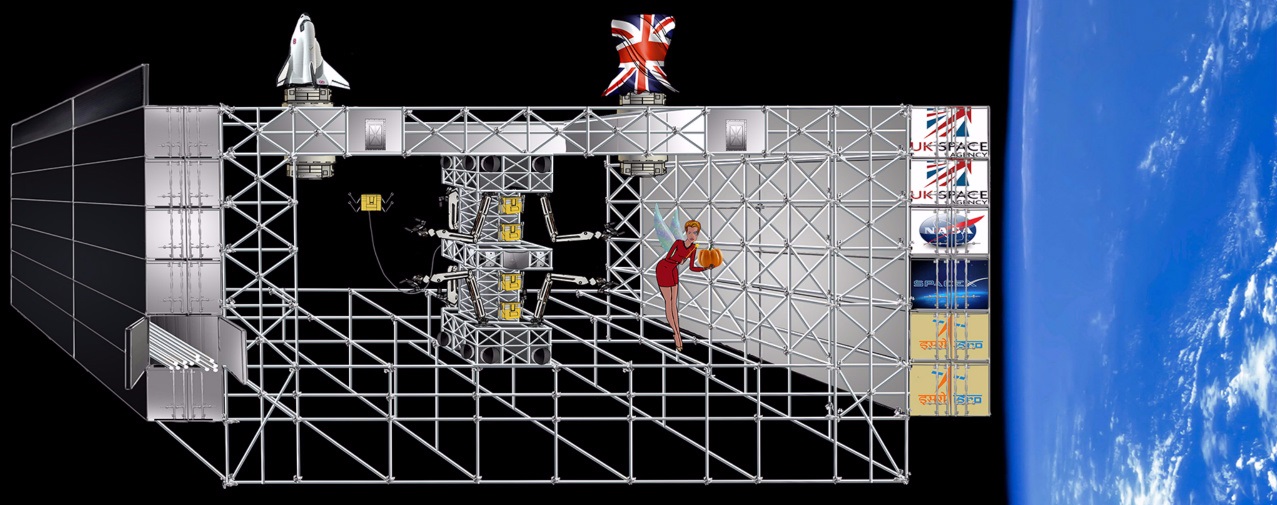

Prior to Humanity attempting any large Mars venture, Humanity should plan to expand by building Near Earth Orbiters. [see below] This design [or any design] could be lightly assembled in Luna orbit from steel mined and forged from undeground established steel works, accessed by tunels built from a north cratater town on the moon.

Near Earth Town Orbiters will be essential to 1) Guarentee human survival 2) A space future [before it becomes too difficult] 3) Somewhhere [for growing numbers] to get some peaceful respite from the ardours of storm life on Earth [Phase: End interim pre-glacial period]

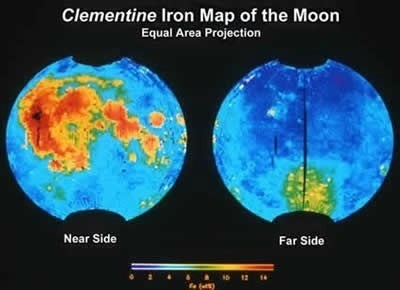

In order to construct Near Earh orbiters 'we' must exploit our asset the moon. Iron is abundent close to the surface on the nearside of the moon [thanks to our 'Earth' tidal infuence during the moons formation after the Theia impact] The north crater will allow a temperature regular moon base and underground access to building lateral tunells to access iron rich sub--terranian ground. Mineworks should be linked to cave foundaries for fabricating the steel giurders necessary to condtruct the Town orbiters. Because of the low gravity and therefore lowered construction / assebly stresses the limit / requirements of girder size and the mass limits of the building design will be increased and decreased accordingly compared to what we experience as limits on Earth.

To that effect, Here is a plan option :

Philosophical design ethos anecdotal :

There are 2 principle schools of thought when it comes to vehicle design. 1. A fully integrated long lasting multi role unit. 2. A modular unit purpose, inter changable replicable units designs.

http://www.wellington-hawk.com/what-we-do/

Analogy: Clothing:

1) Design a onsie from the shoes to the hood including integrated belt and, dual toileting, multi pocketed, stain resistant, porous, insulated, smell retardant with Teflon coated hardened fibres.

2) Or Keep everything separate replaceable interchangeable and by its nature not requiring the complexity to overcome the many and varied problems that would arise from the various restrictions arising from the onsie design ethos.

[When it comes to space suits there is a need for such a system but otherwise not. NASA chose a single complete integrated design for their reusable shuttle, following the design ethos of aircraft design history. For that matter NASA chose to use Von Brown’s static vertical launch V2 weapon as the base for all their launch purposes. My point is that by choosing a one ‘integrated’ system the endeavourer could be taking the road along challenging complexity, when a component for purpose system could eliminate overcoming complex integration.

For instance [1] the shuttle could have been designed to have a principle chassis that onto which could have been bolted a varied sized crew and cargo units to suit duration and cargo purpose, along with rocket motor choices and fuel tank choices. Bolted underneath, a reusable, replaceable, detachable heat shield subsection unit/s. [2] Rocket science could have been simplified by utilising the existing flight platform to reduce the fuel need and reduce the initial atmospheric resistance during static launch. A blended wing body tray, multi engined launch plane]

Inspiration:

During the production frenzy of the Second World War, Britain had 2 small fighter aircraft designs and 3 principle long range bombers of varied capacities. Britain needed a medium sized, fast, long range multi role fighter bomber. Unfortunately there was not enough aluminium or steel to achieve this need. In 1938 Geoffrey De Havilland put forward the DH.98 design later to be named the Mosquito. Its monocoque fuselage and wing were made of wood along with many other components, keeping the need for metals to a minimum. The wooden construction methods not only saved weight but also simplified production and reduced construction time.

The final prototype using 2 Rolls Royce Merlin engines outpaced a Super Marine Spitfire at 6,000 ft. In final production it was capable of 439 mph 20 mph faster than the Spitfire. The British government commissioned all furniture manufacturers to manufacture the De Havilland Mosquito.

6710 were built in the three remaining years of the war. My favourite aircraft of the Second World War.

This story forms the basis of my approach to design and construction. Simplicity, durability and availability.

There is a huge difference in stress requirements between getting into space and re-entering compared to just being in or travelling in space. To design vehicles for space or the moon requires greatly reduced parameters especially when utilising a modular compatible systems approach.

NASA’s Apollo program was a one off race design. Imagine a more step by step program. Putting 2 orbiting box framed docks, one around earth and one around the moon. Putting together a transitter between them, stocking both with supplies and redundant backups of fuel, water, scrubber material and other life backups and finally moving Luna landers and orbital and Luna habitats into place.

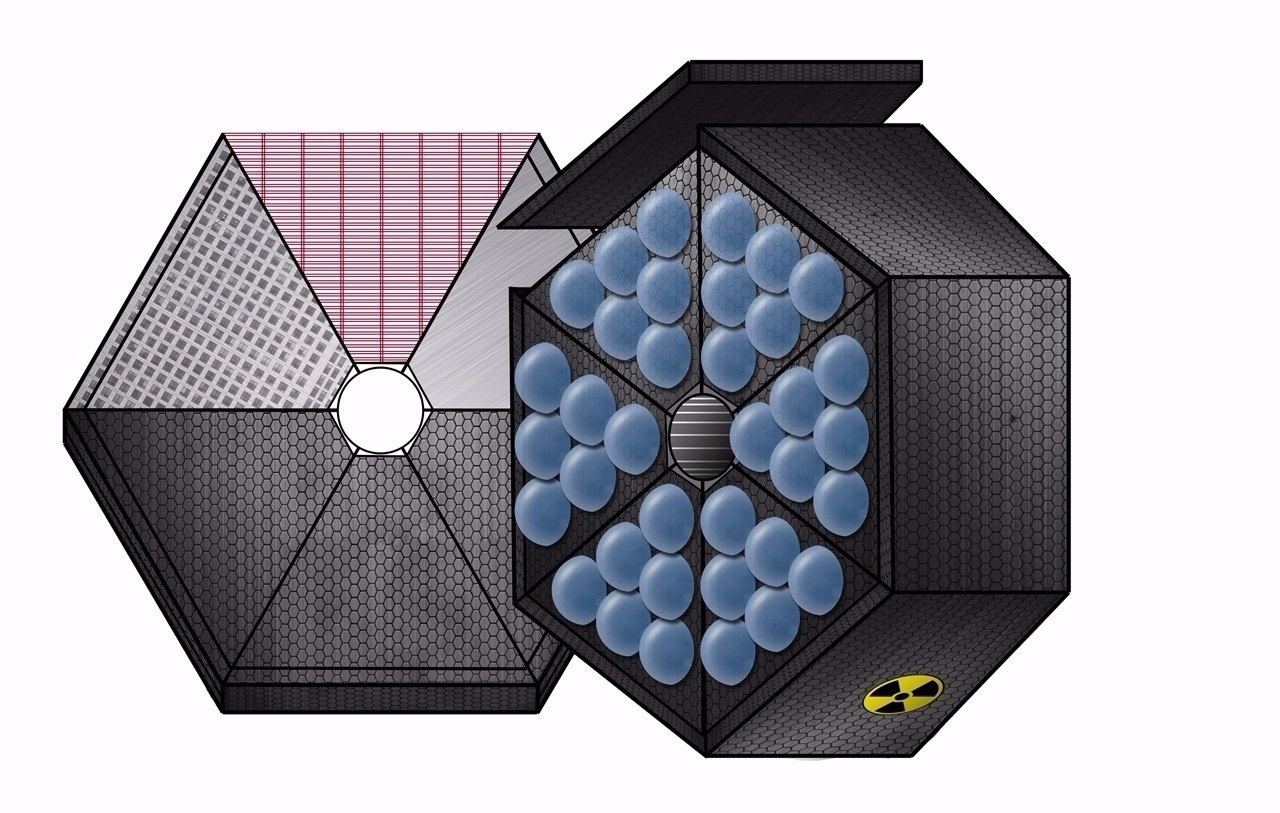

Technologies that are used in construction and cargo transport on earth would be over engineered for use in space. The same designs could be used in space but with reduced tolerances and weight. E.g. Building and maintenance scaffolding. Tubular steel or alluminium with bolt on connectors. Any box size or any rectangle needed. Bolt everything onto it, into it. Spin it end over. Propel it. Bolt it to others. Propel and Spin them all. Inside the frame and bolted to the outer points, habitats. Outer level 1G / inner levels reducing by .1G per level. They can be spherical but they don’t need to be. A sea container design could be reduced in structural weight and strength for cargo, or with a swimming pool membrane as an inner hull seal. [uneccesary but as an example of an existing technology reducing construction cost.] It could be flat packed but probably uneeded with the new heavy lifters being devolped. A much more useable shape that would sit flat on the Luna surface and sub surface. Delivered by a transiter/lander utilizing the very same/similar corner connectors. My Transit truck vehicle design* can ferry and Luna land up to 4 x 52ft x13ft x13ft sea ship like containers {a bespoke 16mx4mx4m units} subject to weight and lifter container diamention design.

Transit truck vehicle*A brilliant base design that I have taken and augmented for real practical use.

http://www.wellington-hawk.com/

As a principle, Transitor and all Luna designs will be adjustable for a Mars venture, along with specific longe range and long duration add on units.