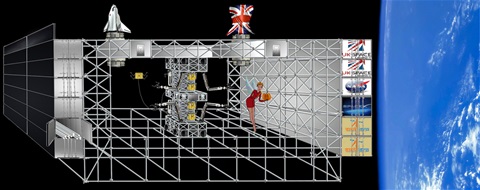

HMS Space - Earth Orbit Assembly & Transit Port

A geodetic frame port with habitat and cargo store and transit containers.

The most cost efficient structure, using existing technologies adapted with a repeating modular design. Remote operated or occupied. Solar powered.

Utilizing existing technologies. Assembled in orbit using existing launch services. Cost effiency priority.

Primary remote docking hub launch1.

http://www.wellington-hawk.com/what-we-do/

Inspiration:

During the production frenzy of the Second World War, Britain had 2 small fighter aircraft designs and 3 principle long range bombers of varied capacities. Britain needed a medium sized, fast, long range multi role fighter bomber. Unfortunately, there was not enough aluminium or steel to achieve this need. In 1938 Geoffrey De Havilland put forward the DH.98 design later to be named the Mosquito. Its monocoque fuselage and wing were made of wood along with many other components, keeping the need for metals to a minimum. The wooden construction methods not only saved weight but also simplified production and reduced construction time.

The final prototype using 2 Rolls Royce Merlin engines outpaced a Super Marine Spitfire at 6,000 ft. In final production, it was capable of 439 mph 20 mph faster than the Spitfire. The British government commissioned all furniture manufacturers to manufacture the De Havilland Mosquito.

6710 were built in the three remaining years of the war. My favorite aircraft of the Second World War.

This story forms the basis of my approach to design and construction. Simplicity, durability and availability.

There is a huge difference in stress requirements between getting into space and re-entering compared to just being in or travelling in space. To design vehicles for space or the moon requires greatly reduced parameters especially when utilizing a modular compatible systems approach.

Technologies that are used in construction and cargo transport on earth would be over engineered for use in space. The same designs could be used in space but with reduced tolerances and weight, with little adapting. Existing commercial Tubular alluminium scaffolding could be used without need for alteration. Any box size of any rectangle needed. Bolt everything onto it, into it. Spin it end over. Propel it. Bolt it to others. Outer level 1G / inner levels reducing by .1G per level.

They can be spherical but they don’t need to be. A sea container design could be reduced in structural weight and strength for cargo or a swimming pool membrane as a final inner hull seal. [unecessary but an example of an existng technology to reduce cost.] A much more useable square shape that will sit flat on the Luna surface or sub surface. Delivered by a transitor / lander design utilizing a universal corner connector.

Vanguard is engineered for 250 ATM to achieve a service of 100 ATM? Above is only a service need of -1 ATM.

The main issue has been the problem of deployment and until recently the vast cost and the need to keep size and weight down, at the maximum limits of the past. This has kept module construction in single light units and favored a tubular design. However recently payloads went from a long standard 10,000 kilos to 20,000 kilos. With a new breed of ‘heavy lifters’ in development the weight limits that are being hinted at range between 40k kilos to 150k kilos.

This means that not only will heavier loads be possible and further made cheaper per ton but also design restrictions can be loosened up. Many will continue without change but a new ambition can free our thinking.

At currently acceptable 20 ton payloads {with big increases in payload limits in development by many countries and private ventures} and utilizing low tech options, Earth Oribit assembly Port - Could be in Orbit and opperational within 3 years away from concept.

Luna Orbit Port 1 could be in place 5/6 & Luna Base 1 'New London' Could be under way year 6/7. Mining and steel product arrival within 20 years.

Luna Lander / Light Transitor assembly design 1: W-H

Earth re-entry vehicle design option 1: W-H {Probable adequate shelf product} - [current 2 western developments known}

Cost effiency priority.

[Design frame option 2: A rectangle habitat station or Hotel with 4 c-gravity decks per slice. Solar powered to an offset fixed rotating configuration.]

Below is a 700 meter x 200 meter Space Station. Constantly Rotating with a neutrally counter rotating center dock. Luna Steel - Luna Orbit assembly.

There are 194 primary buyers. The use of New London along with the big sales, rents, levies and taxes for any allies and trade deals to gain access to New London, transit accommodation and the established mine face [to this coming Klondike] and our tunneling and mining facilities.